What is a die cutting machine?

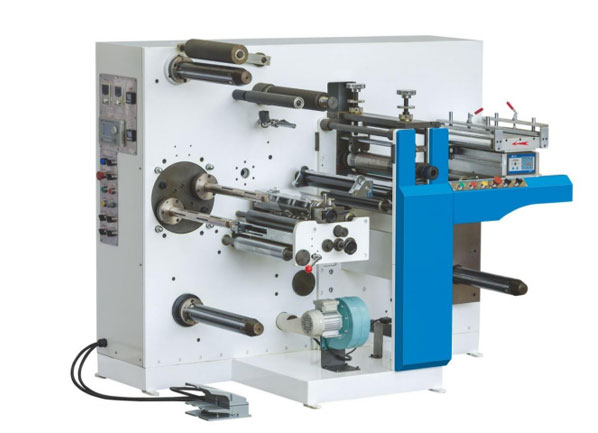

A Die Cutting Machine is a specialized equipment used in manufacturing and packaging industries to cut or shape materials into specific designs using a die.

Dies are sharp, specially shaped blades that are pressed against the material to cut it into the desired shape.

These machines can handle a wide range of materials such as paper, cardboard, plastic, rubber, foam, and even metals depending on their configuration and capabilities.

Key features and capabilities of Die Cutting Machines include:

Precision: They offer high accuracy and consistency in cutting shapes, ensuring uniformity in production.

Efficiency: They can process materials quickly and are capable of handling large volumes of production.

Versatility: They can be used for various applications such as creating packaging boxes, labels, stickers, gaskets, and more.

Automation: Modern Die Cutting Machines often include automated features such as automatic feeding, cutting, and stacking, which improve productivity and reduce labor costs.