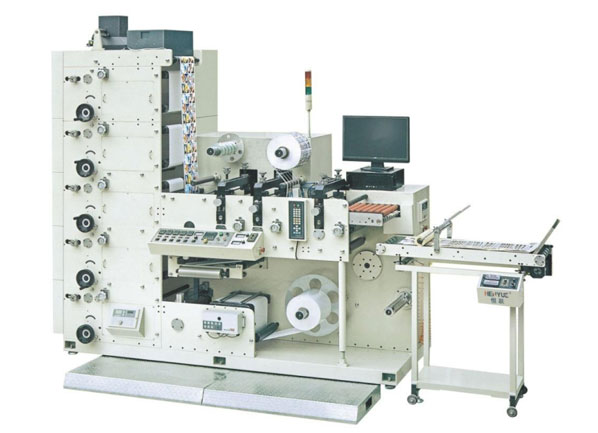

Features of RY-320/480-D Vertical Printing Machine

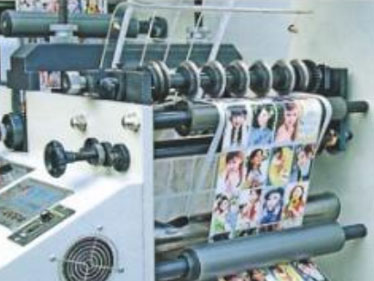

1. Anilox rollers are used to transfer ink.

2. Unwinding and winding are controlled by magnetic brake and clutch.

3. 360-degree register is used in the printing unit.

4. Each printing unit is equipped with a set of infrared drying device.

5. The rubber rollers are automatically disengaged when stopping the machine, and the machine operates at a low speed to avoid drying of ink.

6. The main motor is equipped with imported inverter and stepless speed regulation.

7. Unwinding, printing, varnishing, infrared drying, laminating, and rewinding are completed in one time.

8. It is the best choice for printing enterprises to print self-adhesive labels and other commercial labels.

| Model | Printing Speed | Printing colour | Max.web width | Max.printing width | Max. rewinda & unwind diameter | Printing girth | Precision of overprint | Dirensions (LxWxH) | Machine weight | Total power |

| RY-320 | 80 m/min | 1-6 colour | 330mm | 320mm | 700mm | 175-420mm | ±0.10mm | 3730x1150x3000mm | 3500kg | 10.5kw |

| RY-480 | 80 m/min | 1-6 colour | 490mm | 480mm | 700mm | 175-420mm | ±0.10mm | 3730x1310x3000mm | 4000kg | 15kw |

RY-950-5 Flexo printing machine is hydraulically lifted, eliminating the need for manual loading and unloading of roll materials. Suitable for paper cup, paper bag, paper bowl and so on.

RY-320-5 Label Printing Machine uses a sophisticated printing system to achieve high-precision printing. Suitable for self-adhesive label, and other paper production.

HJA-1150/1270/1450/1650/1850 Horizontal Flexo Printing Machine are equipped with a printing unit roller pillow design, for quick order change without tools. The Unique support structure for precise fine-tuning of pressure.

HJ-650/950 Servo Horizontal Flexo Printing Machine adopts servo motor drive mode and CCD automatic alignment, which can maintain stable alignment during acceleration and deceleration.

GET A QUOTE