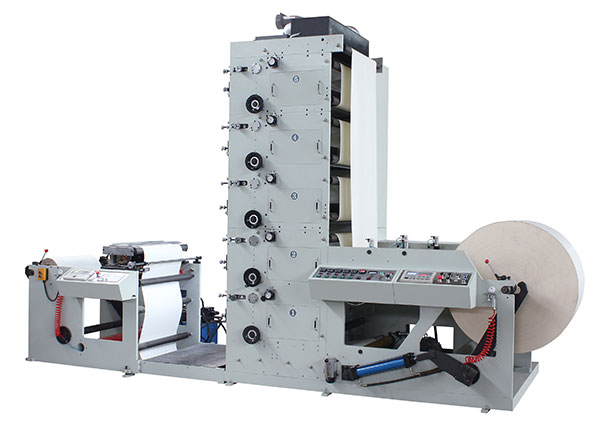

RY-950-5 Flexo Printing Machine is an indispensable and important equipment in the modern printing industry. One of its core parts, the ceramic anilox roller, plays a key role in the printing process with its excellent performance. This anilox roller made of advanced ceramic materials not only inherits the durability of traditional metal rollers, but also achieves significant improvements in wear resistance, corrosion resistance and thermal stability, greatly extending its service life. Reduce replacement frequency, thereby effectively reducing production costs.

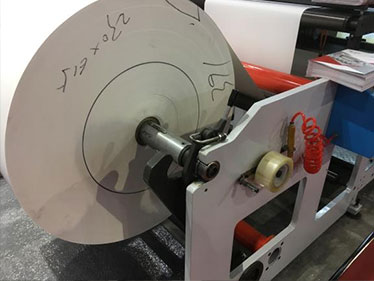

| Max unwinding diameter | 1200mm |

| Printing repeat | 175mm-430mm (56T – 135T) or 255mm-620mm (81T - 195T) |

| Max width | 960mm |

| Max printing width | 950mm |

| Power supply | 380V 3PH 50Hz |

| Total power | 36KW |

| Machine speed | 0-80m/min |

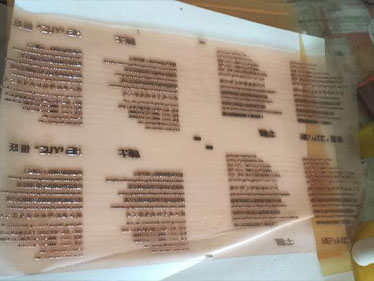

| Printing plate thickness | 1.7mm |

| Double glue tap thickness | 0.38mm |

| Printing precision | ±0.15mm |

| Air shaft diameter | 3inches |

RY-950-5 Flexo printing machine is hydraulically lifted, eliminating the need for manual loading and unloading of roll materials. Suitable for paper cup, paper bag, paper bowl and so on.

RY-320-5 Label Printing Machine uses a sophisticated printing system to achieve high-precision printing. Suitable for self-adhesive label, and other paper production.

HJA-1150/1270/1450/1650/1850 Horizontal Flexo Printing Machine are equipped with a printing unit roller pillow design, for quick order change without tools. The Unique support structure for precise fine-tuning of pressure.

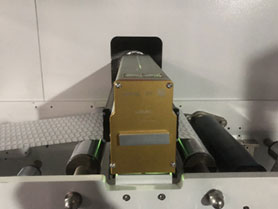

HJ-650/950 Servo Horizontal Flexo Printing Machine adopts servo motor drive mode and CCD automatic alignment, which can maintain stable alignment during acceleration and deceleration.

GET A QUOTE