What is a flexo printing press?

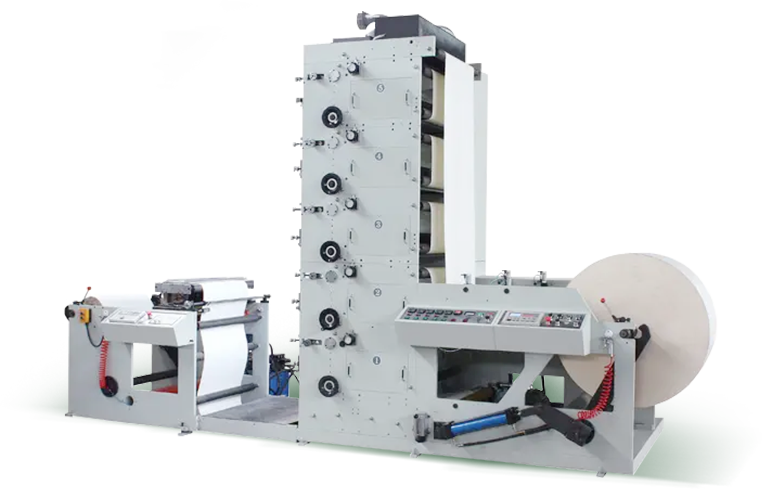

The Flexographic (flexo) printing press is one of the most efficient and consistent printing tools that we have in the market today, for all medium & long run print applications.

Flexo continues to be the most popular of all web-fed technologies that has been deployed throughout the printing industry.

A flexo press uses flexible photopolymer printing plates to imprint images across a wide range of surfaces, making it one of the most efficient methods for large volume requirements.

There are several types of flexographic printing machines:

Stack Press: It is suitable for shorter print runs and is often used for labels and flexible packaging.

CI Press: CI presses are ideal for high-speed, long print runs, and are commonly used for flexible packaging and corrugated board.

Inline Press: Inline flexo presses have all the printing units arranged in a line, allowing for a compact design and efficient production process.

Wide Web Press: Wide web presses can accommodate multiple printing units for color printing.

Narrow Web Press: Narrow web flexo presses are designed for printing on narrower substrates. Used for various applications requiring high-quality printing.